The Versatility and Importance of Centrifugal Pumps in Auto Repair, Farm Equipment Repair, and Generator Installation/Repair

Introduction

Welcome to Michael-Smith-Engineers.co.uk, where we provide top-notch solutions for auto repair, farm equipment repair, and generator installation/repair. In this article, we will delve into the world of centrifugal pumps - essential devices that are widely used across these industries and many others. Centrifugal pumps are instrumental in various applications, facilitating the fluid movement, and ensuring efficient operations.

Understanding Centrifugal Pumps

Centrifugal pumps are dynamic machines designed to convert mechanical energy into fluid flow kinetic energy. Their construction includes an impeller and a casing, which work together to create a centrifugal force. This force moves the fluid through the pump, generating pressure and facilitating its transfer from one location to another.

Benefits of Centrifugal Pumps

Centrifugal pumps are favored in the auto repair, farm equipment repair, and generator installation/repair industries due to their numerous advantages. Here are some key benefits:

1. Efficient and Reliable Performance

Centrifugal pumps are known for their efficient and reliable performance. They offer high flow rates and consistent pressure levels, enabling smooth operations in demanding environments. These pumps are designed to handle various liquids and maintain their performance even with challenging fluids.

2. Versatility and Wide Range of Applications

One of the greatest advantages of centrifugal pumps is their versatility. They find applications in a wide range of industries, and specifically in auto repair, farm equipment repair, and generator installation/repair. In these sectors, they are commonly used for coolant circulation, fluid transfer, and hydraulic systems, among other purposes.

3. Cost-Effective and Low Maintenance

Centrifugal pumps are designed with efficiency and longevity in mind. They require minimal maintenance, resulting in cost savings for businesses. Additionally, their robust construction and reliable performance contribute to reduced downtime, ensuring a continuous workflow and minimizing repair expenses.

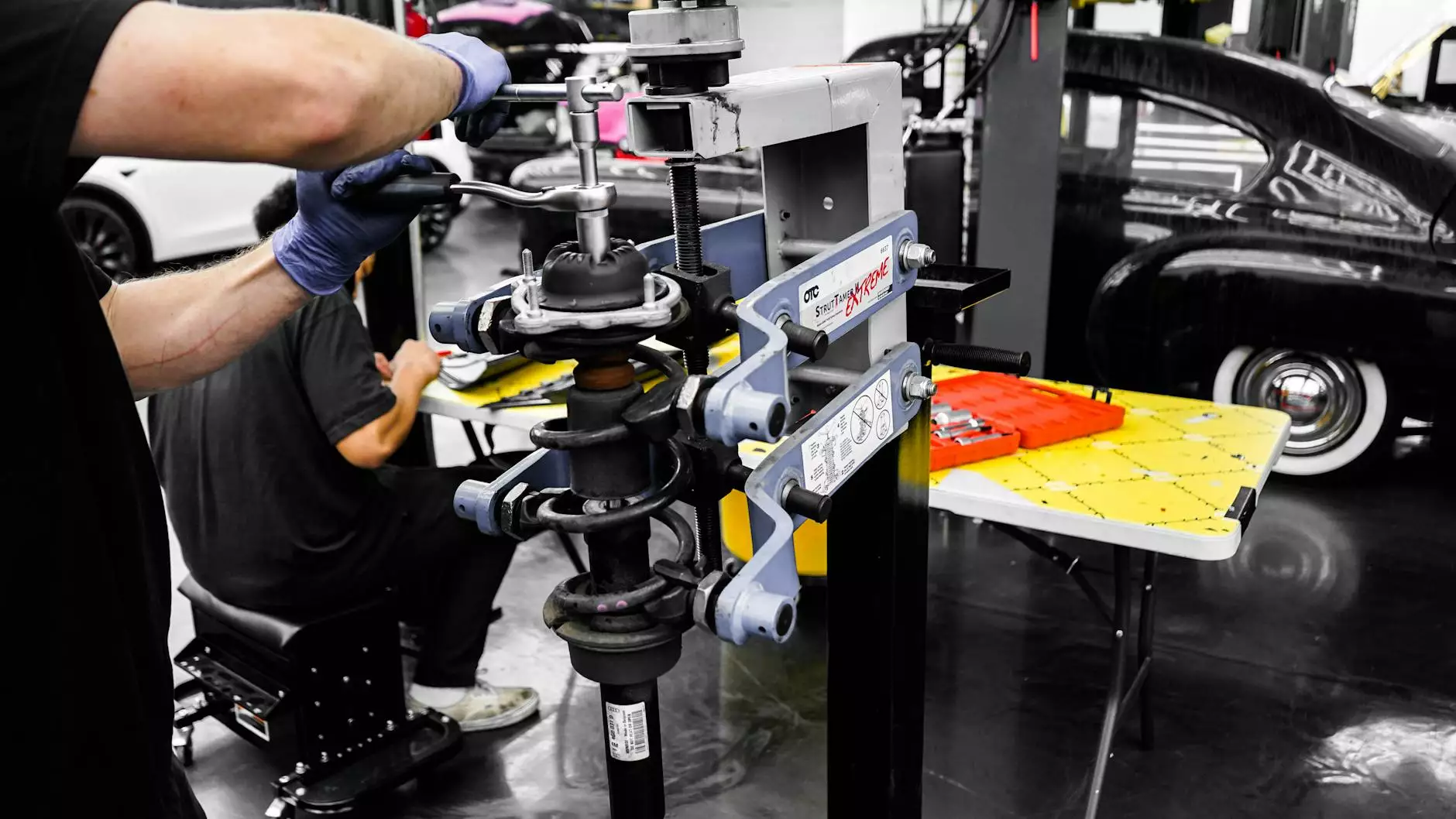

Applications in Auto Repair

In the auto repair industry, centrifugal pumps play a pivotal role in various operations, providing efficient fluid transfer and circulation. Some common applications of centrifugal pumps are:

1. Coolant Circulation

Centrifugal pumps are often employed in coolant systems to ensure effective heat dissipation, maintaining optimal engine operating temperatures. These pumps help prevent overheating and potential engine damage, allowing vehicles to perform at their best.

2. Brake System Hydraulic Pressure

Another crucial application of centrifugal pumps in auto repair is the generation of hydraulic pressure for brake systems. This ensures reliable and responsive braking, contributing to vehicle safety on the road.

Applications in Farm Equipment Repair

In the realm of farm equipment repair, centrifugal pumps prove invaluable for optimizing agricultural operations. These applications include:

1. Irrigation System

Centrifugal pumps play a critical role in irrigation systems, facilitating the transfer of water from sources such as wells, rivers, or lakes to fields. These pumps provide the necessary pressure to ensure consistent water supply, enabling efficient crop growth and maximizing yields.

2. Liquid Fertilizer Distribution

Efficient distribution of liquid fertilizers is essential in farms. Centrifugal pumps aid in delivering fertilizers to crops, ensuring even coverage and promoting healthy growth. Their precise control mechanisms and ability to handle corrosive substances make them ideal for this task.

Applications in Generator Installation/Repair

Centrifugal pumps are also vital components in generator installation/repair. Their applications in this field include:

1. Cooling System

Generators require effective cooling systems to prevent overheating during prolonged operations. Centrifugal pumps efficiently circulate coolant, dissipating excess heat and allowing the generator to run optimally. They ensure the performance and reliability of these critical backup power systems.

2. Fuel Transfer

Fuel transfer is another crucial function in generator installations. Centrifugal pumps aid in transferring fuel from storage tanks to generators, ensuring a continuous fuel supply and reliable operation during power outages or emergencies.

Conclusion

In summary, centrifugal pumps serve as the backbone of various industries, including auto repair, farm equipment repair, and generator installation/repair. Their versatility, reliable performance, and wide range of applications make them indispensable for fluid transfer, circulation, and maintaining optimal operational conditions. At Michael-Smith-Engineers.co.uk, we understand the importance of high-quality centrifugal pumps for your business needs. Contact us to explore our comprehensive range of centrifugal pumps and benefit from our expertise in providing top-tier solutions for your industry.